Can't find it in our guide?

If you cannot find your engine in our model guide, please check your engine for below measurements and compare with any of our existing propellers if they may match. Measure the propeller diameter, shaft diameter and number of splines (teeth). It is also necessary that the engine gear housing will meet the propeller hub in a correct way. Finally measure the thrust washer so it can be checked if it will fit with any of our propellers. Please have a look at each picture below for help. If you have any questions or need for further explanation, please contact us.

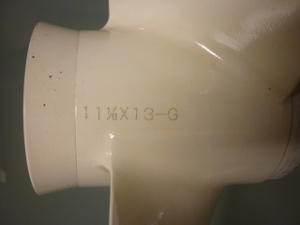

Step 1

Locate markings on the existing propeller that could inform you about the diameter and pitch. The picture shows a typical marking where the first figure 11 1/8 is the diameter and the second, 13 is the pitch setting. Both settings are measured in inches. The markings can be located in different positions, in- or outside the hub. Some propellers do not have this requested marking, just a part number from the manufacturer.

Step 2

If the diameter is unknown, measure it as shown on the picture. Measure from the center of the shaft hole to the blade tip. Multiply with 2 to get the diameter. Most propeller dimensions are stated in inches (1 inch = 2,54 cm or 25,4 mm). Divide your measured value with 2,54 or 25,4 depending on if you measure in cm or mm. You should get a value in the range of 10-15 inches. The more horsepower you have the larger propeller is needed.

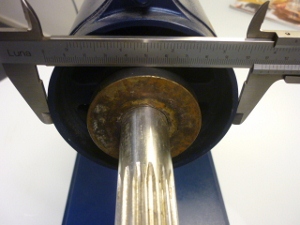

Step 3

Measure the shaft outer diameter with a calliper or other suitable device. The measurement is taken on top of the so called splines (largest possible diameter). Typical dimensions are 18, 19, 23, 25 and 28 mm. They are all approximate being converted from inches. The largest propeller uses the largest shaft diameter.

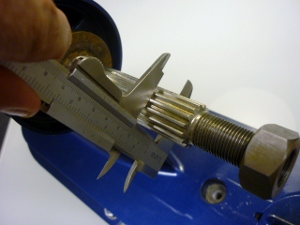

Step 4

Count the number of splines teeth. Compare with each propeller specification sheet to possibly find a match. Our models has 10, 13, 14, 15, 17 and 19 splines. The number of splines are to some extension related to the propeller size.

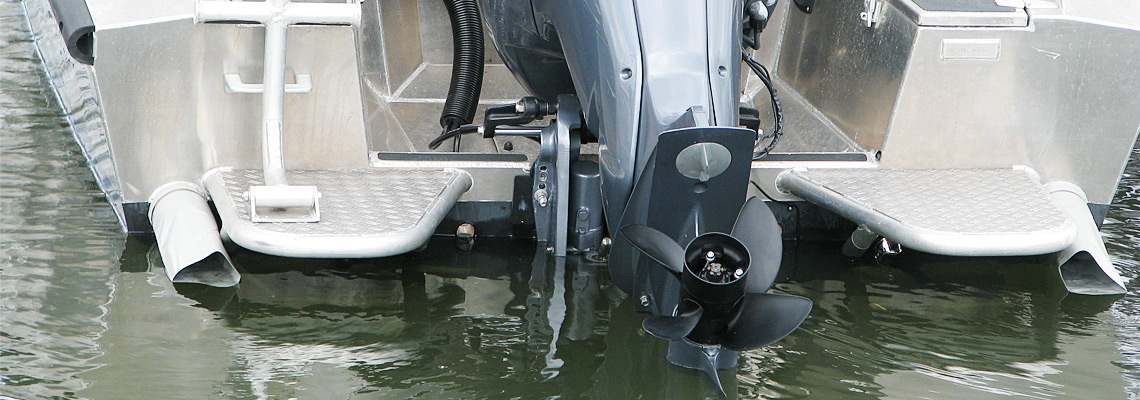

Step 5

Measure the outer diameter of the gear housing. The propeller hub must correlate with the gear housing so the water flow can reach the propeller without any interruptions. The propeller hub dimensions are given on the specification sheets.

Step 6

Measure the inner diameter. Most propellers has an flange that shall intersect with the gear housing. This is meant to prevent exhausts to find its way out between the propeller hub and the gear housing.

Step 7

Finally, measure the so called thrust washer. This belongs to the engine as an original part. The washer shall meet the propeller adapter in the best possible way, surface-to-surface. The picture shows a typical thrust washer usually made of stainless steel.

N.B. When taking the original aluminium propeller off, it is rather common that this washer is stuck into the propeller hub and therefore looks like it belongs to the propeller. Mounting any new propeller without this washer will cause major damage to the shaft sealing in a few minutes of driving.